Strategy Workflow

Source file: 1. strategy-intro-new-workflow.htm

Introduction to Strategy

Strategy is a strategic scheduler that focuses on two streams of optimisation: cut-off grade and net present value (NPV). The algorithm implemented in Strategy allows you to achieve this optimisation by manipulating the cut-off grades and the mining order for each bench and stage. Moreover, the optimisation process is run on remote, cloud-based servers, which results in returning optimal schedules in a minimum of time.

The schedules generated by Strategy can be used for one or more mining operations. As in Origin Blocks, setups contain block models, however, individual blocks are not scheduled by rank. Instead, areas of the block model are divided by stage, bench and lithology and scheduled by period accordingly.

With Strategy, you can plan mining operations using multiple processing scenarios and find solutions to the following issues:

-

Specifying the optimal cut-off grades for each process and stockpile in each period.

-

Specifying an appropriate production rate for a mining operation.

-

Finding the optimal stage and bench mining order in all pits.

-

Finding the ideal processing capacities and targets for different plant processes.

-

Determining when the plant processes should have their capacity increased.

-

Determining the ideal size for the operation's haulage fleet, and when it should be increased.

Evolution allows you to configure the above-listed settings and, at the same time, set the constraints that the software will have to obey or try to meet. These constraints include, but are not limited to, the following:

-

Head grade limits

-

Minimum and maximum production rates.

-

Sink rate

-

Stage availability in each period

-

Stage bench turnover

For more information on the constraints available in Strategy, see Constraints.

Strategy allows you to check the results of the optimisation by the use of various reporting tools. For more information on reporting in Strategy, see Reporting.

Multi-element schedules

Evolution has introduced multi-element schedule generation, where primary elements and secondary elements are configured using attributes from the imported block pits. Cut-off grades and revenue streams will be calculated for primary elements, while only revenue will be calculated for secondary elements. See Single and multi-element setups for more information.

Strategic level of detail

Evolution's Strategy is targeted at solving strategic-level questions, and hence it works on a corresponding level of detail. It is most suitable for pre-studies and feasibility studies, and can also be applied to the life-of-mine schedules. It is designed to sit in between the level of detail and accuracy provided by pit optimisation processes, and block-by-block schedulers such as Evolution Origin and Epoch.

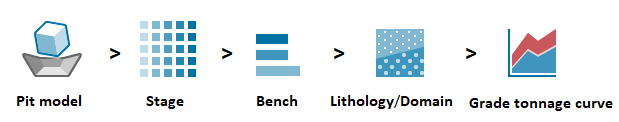

During scheduling operation, Strategy aggregates all pit models into the following data structure:

Note: Grade bins are used instead of a grade tonnage curve for multi-element projects.

In addition, the mining sequence is assumed to be top down, bench by bench within a stage; that is, a bench must be completely mined within a stage before mining can commence on the bench below.

This structure provides for lower optimisation run times, while still providing accuracy befitting of a strategic study. In tactical schedules with monthly scheduling periods, these simplifications might prove to be unworkable, as the ability to target high-grade areas of multiple benches within a stage at the same time is lost. However, with the appropriate use of staging to separate areas of high-grade ore, some of these limitations can be worked around, since Strategy is free to mine for multiple stages simultaneously.

Strategy workflow

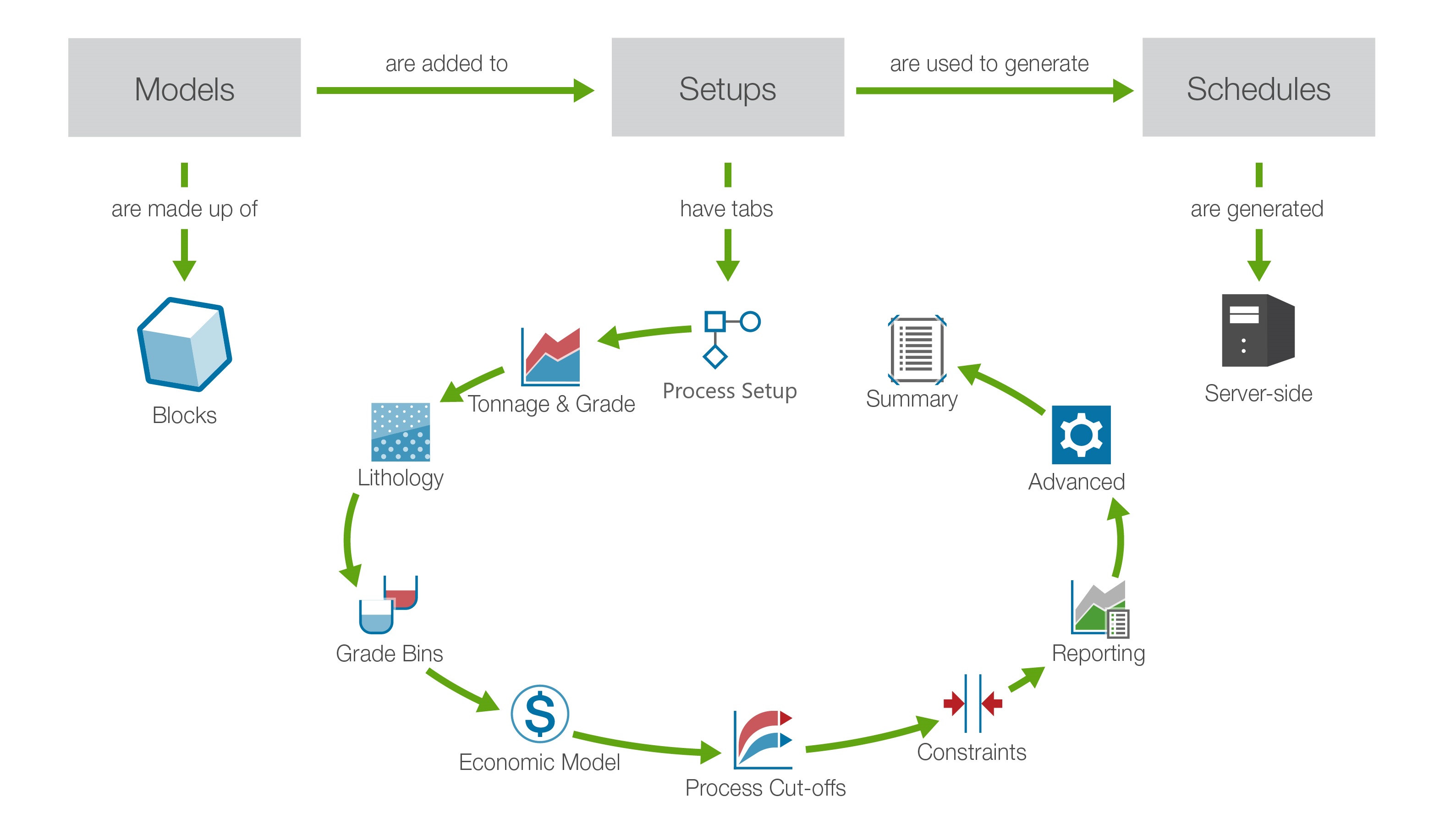

The workflow in Strategy can be divided into three main stages: Models, Setups, and Schedules.

Models

Strategy uses block model representations of any pits in the mining operation. These pit block models will typically have multiple stages, phases, and shells that are designed with the consideration of practical mining, and to bring revenue forward in time. These pit models are often the output of pit optimisation software programs, such as Maptek Vulcan Pit Optimiser.

Setups

Setups are used to model the mining operation, or a particular scheduling scenario. A setup specifies the following elements:

-

Material flow definition between pits, dumps, stockpiles, and mils

-

Mining and processing capacities, as well as their targets

-

Capital and operating costs, as well as the revenue obtained from the operation

-

Practical mining constraints, such as the availability of pit stages, bench turnover, or blend targets

Schedules

Schedules are created by submitting a setup to the remote cloud servers. This is often called running a job. During this process, Strategy’s algorithm determines an optimal schedule for NPV, and returns it in the form of a result.

Scheduling process

The Strategy Workflow establishes the key steps to set up and analyse your long-term schedule. To get started, you can click on the steps below:

-

Create a Setup

Initialise an unconfigured Strategy setup. -

Configure the Setup

Add information to each configuration tab of the setup consequentially. The information added is based on the attributes of your imported model(s). -

Validate the Setup

Confirm that the right information has been provided in each configuration tab of your setup. -

Generate a Schedule

Submit your setup to the server for processing to generate your schedule. -

View the Schedule

Download and view your schedule. You can also read Evolution’s reports. -

Analyse the Schedule

Analyse your results using pivot reporting. To analyse data externally, Evolution provides a number of export tools.